Dear All,

LPG storage and the related safety considerations have been discussed many times on various threads on 'Cheresources'. Any reader / member of 'Cheresources' can find these threads using the search facility on 'Cheresources'.

Today's blog entry presents the British perspective on safety related to bulk LPG storage. The reference for this blog entry has been provided at the end of this blog entry. Let us understand what the British view on safe LPG bulk storage means:

Safe storage and handling of LPG is of paramount importance, whether it is in bulk or in cylinders. This is basically achieved by ensuring the mechanical integrity of the storage vessels or cylinders and by strict observance of the recommended separation distances between storage and buildings or boundaries. This passive protection has to be supplemented by rigorous observance of operational procedures. The Liquefied Petroleum Gas Association (LPGA) has issued a Code of Practice on bulk LPG storage at fixed installations in collaboration with and approval of the Health and Safety Executive. Part 1 deals with design, installation and operation of vessels above ground.

Note: UKLPG was formed by the merger of the LP Gas Association (LPGA) and the Association for Liquid Gas Equipment and Distributors (ALGED) in January 2008. Its roots are firmly established, with LPGA and ALGED established in 1947 and 1975 respectively.

Perhaps the most serious hazard to LPG storage is that of accidental fire. The safety distances are intended to separate the storage from possible adjacent fires so that the risk of a fire affecting the storage is very low. However, this residual risk has to be catered for. The mechanical integrity needs to be assured under severe fire attack. For this reason, the vessels are provided with relief valves designed to cope with fire engulfment. The heat from such a fire may raise the stored pressure until the relief valve opens. The discharge capacity of the relief valve when fully open is required to meet or exceed the following:

Q = 10.6552*A0.82

where:

Q = Relief Valve capacity in m3/min of air @15°C, 1.01325 bar (abs)

A = total surface area of the vessel, m2

The heat transfer to the liquid from an engulfment fire has been estimated at around 100 kW/m2, and the above formula equates this to the vapor produced from this input as latent heat. The exponential is an area exposure factor which recognizes that large vessels are less likely to be completely exposed to flames.

The safety relief valve will protect the liquid-wetted areas of the storage vessel. The metal temperature will not significantly exceed the liquid temperature which will be absorbing the latent heat of vaporization. However, above the liquid line no such cooling will take place. The metal temperature at the top of the vessel could therefore exceed safe limits.

The usual protection for large installations is to provide a water-spray system. For small bulk storage, fire hoses or monitors are often adequate. However, for installations over 50 tons of storage (and all major cylinder-filling plants) it is accepted that a fixed water-spray system needs to be provided which is automatically initiated by a system capable of detecting a fire threatening the vessels and/or the adjacent tanker loading or unloading area. The deluge rate to provide protection against fire engulfment is 9.8 liter/min/m2 of vessel surface area, and this should be capable of being sustained for at least 60 minutes. The spray pattern adopted for a fixed installation normally includes four longitudinal spray bars, two at the upper quadrants and two at the lower quadrants of horizontal cylindrical vessels, with nozzles spaced to give uniform coverage.

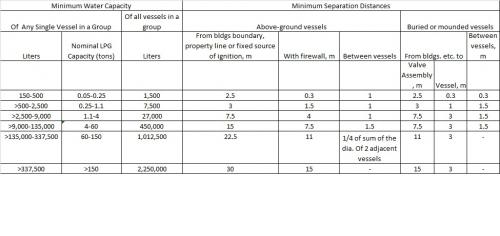

An alternative means of avoiding the hazard from fire is to bury the vessels or to employ the increasingly popular method of mounding. In either case acknowledgment of the reduced hazard is indicated by the reduced separation distances (see attached table). Since either burial or mounding preclude the possibility to monitor continuously the external condition of the vessels, very high-quality corrosion protection needs to be applied, normally supplemented by cathodic protection, depending on soil conditions. Guidance approved by the H.S.E. is published by the LPGA in their Code of Practice 1 part 4.

The use of burial or mounding is sometimes employed to overcome visual environmental objections since the mounding, for instance, can be grassed over. Indeed, this is the method often adopted to prevent erosion of the mounding material.

Hope all of you have enjoyed this small article related to safety on Bulk LPG storage as followed in the UK.

I do expect some comments and will be glad to share my views on the comments.

Regards,

Ankur

Reference: Chapter 14, Plant Engineer's Reference Book , 2nd Edition by Dennis A. Snow

FB

FB

Ankur

I hope you are well. Thank you for all the information that you post. I would like to ask you Can you help me on this one. I have a nitrogen tank that is 7.5522 m high and 2.121m diameter. it comprises two concentric chambers and the distance between the two chambers is 15cm. The walls are mild steel of thickness 1/2 inch. The tank absorbs heat from the sun resulting in the nitrogen inside gaining temperature from -196degC to about -180 degC. Question:

What is the energy gained by the tank i. without any insulation on the outside and ii. with glass wool of thermal conductivity k=0.038W/