Hello everybody!

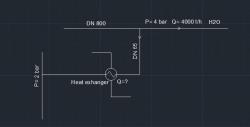

My task is to find out the flow quantity in a heat exhanger on the cold side. We would like to cool a 95°C water with 25°C water.

We have a DN 800 pipe with 4000 t/h water flow and 4 bar pressure. There is a branch with DN 65 pipe across a heat exchanger and we connect a 2 bar system on the end of the pipe.

The force which allows the fluid to move is the pressure difference.

Is it right if I have a given pressure difference and a pipe diameter it determine the flow quantity? Not depends on the flow and velocity in the big pipe?

Thanks for your help

FB

FB