Hi all,

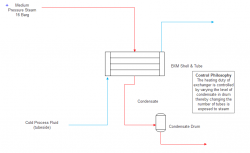

Currently, we have an improvement initiative to substitute the heating medium for an existing heat exchanger from Medium Pressure steam (15 barg) to Low pressure steam (7.5 barg). Obviously with lower pressure steam, the saturation temperature is lower too. Is there a way to calculate the time required for the different steam to heat the process fluid to the target temperature? I would like to know how much longer it takes for the low pressure steam to heat the process fluid.

Note: This is a continuous flowing process, not batch

Edited by Daniel James, 13 June 2016 - 10:51 PM.

FB

FB