|

|

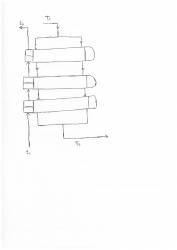

Mtd Correction Factor (Ft) Chart.

#1

Posted 16 June 2016 - 02:28 AM

I am having a problem in estimating the correction factor of MTD (FT) for the attached heat exchanger configuration. The known parameters are t1, t2, T1 & T2.

Any one can guide me to the approperiate FT chart or formula?.

#2

Posted 16 June 2016 - 02:49 AM

Sorry for multiposting that was by mistake while clicking post topic I thought it was not posted.

#3

Posted 16 June 2016 - 05:20 AM

I am not sure whether you have understood significance of Ft factor and where it is to be used.

However, in order to calculate Ft factor, you are required to calculate LMTD & caloric temperature. Based on graph as per exchanger geometry, you can get Ft factor.

Forum may be able to help you, if you describe your problem in detail & your understanding clearly about the assignment.

#4

Posted 16 June 2016 - 06:30 AM

#5

Posted 16 June 2016 - 02:28 PM

You can find LMTD correction factor charts for unusual shell types in the following EXCEL spreadsheet:

Process Heat Transfer by Art Montemayor. IT is downloadable and is It s located in the file library.on this website.

#6

Posted 16 June 2016 - 06:21 PM

Hi Said ,

As per Srfish'advice , consider the great resource attached .

Breizh

#7

Posted 19 June 2016 - 02:58 AM

3 series-2 tube pass arrangement in the excel sheet is close to my configuration.

#8

Posted 19 June 2016 - 02:24 PM

Maybe, maybe not. The arrangement you show suggests that the shell side is condensing vapor, and the tube side a single phase cooling media. You need to see the shell baffle detail to get the right configuration. It seems to be primarily cross flow on the shell side.

Bobby

#9

Posted 20 June 2016 - 12:09 AM

The shell side is a process gas and the tube side is Boiler feed water. Please find more details in the attached datasheet of the exchanger.

Attached Files

#10

Posted 20 June 2016 - 09:57 AM

HE-Datasheet1.pdf shows that they are TEMA type DXU heat exchangers. The X indicates cross-flow heat exchangers. You can find LMTD correction factor charts for cross-flow in the Heat Exchanger Design Handbook.

#11

Posted 21 June 2016 - 12:52 AM

Many thanks to srfish for taking my attention towards points mentioned in his post. Hence, I have removed my earlier post.

As a academic curiosity, I run HTRI for given datasheet & noted below.

No. of exchanger in series : 3

Exchanger No. : Hot Inlet, ºC: Hot Outlet, ºC : Cold Inlet, ºC : Cold Outlet, ºC

1 : 340ºC : 280.8ºC : 257.2ºC : 310ºC

2 : 280.8ºC : 235.4ºC : 216.6ºC : 257.5ºC

3 : 235.4ºC : 200ºC : 185ºC : 216.6ºC

I guess, in absence of above data, Said Salim was experiencing problem of estimating Ft factor. Please correct me if I am wrong.

However, concern still remains is how to estimate these terminal temperatures for DXU type configuration, without help of HTRI.

#12

Posted 21 June 2016 - 04:25 AM

#13

Posted 21 June 2016 - 06:17 AM

Well. Now when you have terminal temperature with you for each exchanger in series, you may refer to applicable graphs for exchanger geometry wherein you can read Ft factor directly based on terminal temperature. Well known source can be Kern Book.

Similar Topics

Propane Product Temperature Correction FactorStarted by Guest_loggrrr_* , 20 Nov 2023 |

|

|

||

Predicting Fouling Factor In ReboilersStarted by Guest_ProcessEng_12_* , 12 Aug 2021 |

|

|

||

Psychrometric Chart: High Dry Bulb, Low RhStarted by Guest_elliot.433_* , 13 Jul 2023 |

|

|

||

Looking For Enthalpy (H) – Entropy (S) Chart For Chloromethane (MethylStarted by Guest_fredlan54_* , 18 Jul 2022 |

|

|

||

Wind Enhancement Factor In Kumana Kothari CalculationsStarted by Guest_rlepra_* , 01 Dec 2017 |

|

|

FB

FB