I have been away for 3 weeks from my blog. Well, was busy on the workfront as well as on personal matters. Travelled home to India to be with the family. Spent some brief but quality time with the family who were keen to light one more candle on the cake.

I have been away for 3 weeks from my blog. Well, was busy on the workfront as well as on personal matters. Travelled home to India to be with the family. Spent some brief but quality time with the family who were keen to light one more candle on the cake.Today's blog entry deals with design guidelines for tank truck loading terminals for petroleum products. Notable exclusions from these design guidelines are LP Gases & Cryogenic Liquids.

The guidelines are provided stepwise for the sake of clarity:

Step 1: Establish the product movement by road for a given design year

The following sub-steps need to be determined:

a. Volume per year of each product

b. Peak volumes and time duration

b.1 Peak arrival frequency (trucks per hour)

b.2 Volumes for the peak period

Step 2: Establish truck fleet characteristics & local factors governing road transport

The following sub-steps need to be determined:

a. Vehicle Characteristics

a.1 Truck capacities

a.2 Number of compartments per truck

a.3 Number of products per truck

a.4 Top or bottom loading

a.5 Overall Truck dimensions (Length, Width, Height)

a.6 Minimum turning radius http://www.google.co...iw=1024&bih=571

b. Local factors, preferences, regulations, regarding type of terminal operation

b.1 Terminal operation hours per day and days per year

b.2 Desired degree of terminal automation

b.3 Guidelines or Statutes for Vapor Recovery

b.4 Sequential or simultaneous truck compartment filling

b.5 Metering & Custody Transfer philosophy

c. Average / maximum allowable waiting time per truck during peak periods

d. Terminal Owner preferences or government regulations regarding terminal operation

Step 3: Predict arrival patterns based on local experience for customer demands within the delivery region

a. Peak arrival periods: Trucks per hour & duration (for example morning queues can represent the highest arrival frequency over a relatively short duration)

b. Seasonal Variations: These can be significant for certain products such as motor gasoline, heating oils, fuel oils, asphalts etc.

Step 4: Establish design or base case configuration

a. Group trucks by product loaded

b. Calculate average loading time per truck for each class of product

b.1 Assume one stop loading

b.2 Assume sequential compartment filling unless advised otherwise

b.3 Calculate filling time

b.3.1 Allow for low initial and final top-up rates (Refer attachment)

b.3.2 Base normal filling rates on local practice

- 30 liters/s (500 gpm) for truck capacity less than 15 m3 (4000 U.S.gallons)

- 50 liters/s (800 gpm) for truck capacity greater than or equal to 15 m3 (4000 U.S.gallons)

- Calculate filling time per compartment

= (Total Volume Loaded - Volume loaded in slow start / top-up period) / Loading Rate

(Assume start / top-up filling rate as 10% of normal filling rate)

- Total filling time = Filling time per compartment*Number of compartments

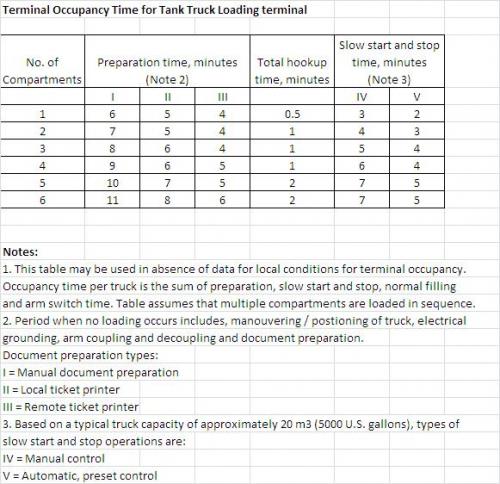

b.4 Include additional time for preparation and hookup (Refer attachment)

b.5 The reciprocal of the total occupancy time in hours gives the number of trucks per hour that can be loaded at each spot

c. For daily peak arrival periods, calculate the number of spots for each product class with 100% terminal utilization

No. of spots = (Peak Arrival frequency, trucks / hour)*(Arrival period, hours)*(Loading time per truck, hours) / (Arrival period, hours + Maximum Allowable waiting time, hours)

d. For peak arrival period in excess of 1-2 weeks, calculate the number of spots required for each product class based on a terminal utilization of approximately 50%

No. of spots = (Volume per peak period)*(Loading time per truck, hrs) / (Vol. per truck)*(Terminal open hrs per day)*(Terminal Open days per year)*(peak days/365)*0.5

e. For overall yearly average loading rates, calculate the number of spots required for each product class based on a terminal utilization of 35%

No. of spots = (Volume / yr)*(Loading time / truck, hrs) / (Vol / truck)*(Terminal opens hrs per day)*(Terminal open days per yr)*0.35

f. Select the highest number of spots resulting from the controlling case above rounded off to the nearest whole number.

g. Attempt to minimize the total number of stops based on the following considerations:

g.1 Reviewing requirements (peak volumes, peak periods etc.)

g.2 Combining spots based on low demand of one product class with another

Step 5: Examine the impact on terminal occupancy and waiting times for the following

a. Simultaneous filling with preset control

a.1 Multiple products per spot

a.2 Multiple loading arms per product per spot

b. Changed (Increased/Decreased) filling rates

Step 6: Other Considerations

a. Provision for future expansion

b. Provisions for washing or inerting trucks

c. Loading arm capacities based on standard arm configurations

d. Fire & Gas Detection and active / passive firefighting

e. Provision of locally or remotely operated emergency shutdown valves for each product line

f. Provision for electrical grounding at all loading spots

The aforementioned write-up tries to provide general guidelines on how to design a tank truck loading terminal. However, to repeat, these are very general guidelines and process engineers involved in design of tank truck loading terminals should follow the specific project requirements when provided to them as a design basis or concept for a given system.

Hope all of you enjoy this blog entry and looking forward to comments and discussion on this topic from knowledgeable members of the community.

Regards,

Ankur.

FB

FB

thank you for the post Mr. Ankur, I find its interesting.