Hello engineers,

I have recent problem with solving the heat transfer from sand(hot) to air(ambient). Newton's law of cooling, convective heat flux is much bigger than sand heat conduction. First layers will get cooler much faster and temperature difference in convection comes so small that there is almost no heat transfer. Thats what my amateur CFD simulation shows, and cant solve the heat equation in 3 dimmensions and dependent on time.

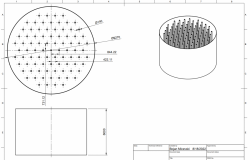

Whats your suggestion, is this simulation correct? Do I need to increase to heat transfer area according to sand heat diffusivity?

How should I approach the problem? ![]()

![]()

![]()

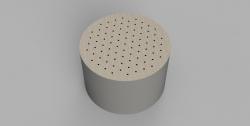

Attached photo (air flows through the small pipes)

Edited by Bojan332, 19 August 2022 - 01:44 AM.

FB

FB