Chemical and Process Engineering Resources

Trickling Biofilters for Hydrogen Sulfide Odor Control

Dec 13 2010 01:36 PM | mwu in Separation TechnologyTest Installations

Wastewater Pump Station Odor Control

Two 55-gallon liquid storage drums with inside diameter of 20 inches were welded together and used as the biofilter vessel. HD Q-PAC® was installed in the tower with the needles oriented vertically. Gaps between the media and the walls of the drums were filled with separated pieces of HD Q-PAC®.

|

| Figure 4: Test Unit at Saco, Maine |

A centrifugal blower rated at 80-100 cfm pushes the air into the biofilter. Contaminated air enters the bottom of the vessel, passes upward through the biofilm-coated media, and exits through the top. H2S inlet concentrations in the pump house air range from 1 to 90 ppmv.

Water is recirculated at 6 gpm. Fresh water with nutrients is added at 1 gpm for 15 min every day. H2S concentrations are measured using a Scott Alert Meter (Model S108) which is calibrated monthly.

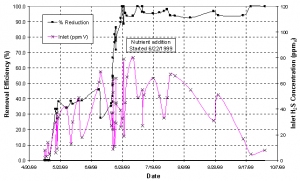

When the biofilter was started up in May 1999, the H2S removal efficiency increased gradually as biofilm developed on the media, but it remained below 45%. A commercial lawn-fertilizer dispenser was connected to the make-up water line to add ammonium phosphate and urea as micronutrients. After that, the H2S removal efficiency rose to over 90% within a few days. Since then, the removal has been consistently over 90%, even though the inlet H2S level varied as much as 400% within the same day.

Throughout the summer of 1999, with recording-breaking high temperatures, the treatment plant did not receive a single complaint about pump station odors.

|

| Figure 5: Hydrogen Sulfide Removal at Windy Hill Pump Station in Saco, Maine |

Central Wastewater Treatment Plant

HD Q-PAC was also tested in a trickling biofilter to remove hydrogen sulfide from exhaust air at the Hyperion Treatment Plant in Los Angeles, California.

This test filter has an inside diameter of 4.5 ft and is packed with 7 ft of media. HD Q-PAC® was installed in the tower with its needles oriented horizontally. Each rectangular module of media was stacked tightly against the others, leaving no gaps between them. Gaps between the HD Q-PAC and the walls of the circular tower were filled in with small pieces of porous rock.

|

| Figure 6: Hyperion Plant Test Unit |

A blower sends untreated air into the bottom of the tricking biofilter. The air flows upward through the biofilm-coated media, while the water trickles down over it. The treated air exits the top of the unit.

The filter was initially used to treat 700 cfm of air containing 2-20 ppmv of H2S. Water was recirculated over the media at a rate of 10 gpm.

The unit was started up by filling the 300-gal sump with secondary effluent from the treatment plant, then running the fan and recirculation pump continuously until bacteria began to colonize the media, and the pH of the water decreased to less than 2.0. After that, a portion of the acidic solution was made to overflow every 4 hours by adding secondary effluent at 3 gpm for 20 minutes.

In addition to controlling the pH, the 360 gallons of make-up water added each day provided micronutrients needed for growth of the biofilm. (Thiobacillus thiooxidans is autotrophic; it uses atmospheric CO2 as its carbon source.)

The H2S concentrations in the inlet and outlet air streams were measured daily using an Interscan Voltammetric Sensor.

The removal efficiency of H2S increased steadily for the first few days of operation, reaching 90% within 10 days.

|

| Figure 7: The Author Installing HD Q-PAC® |

Ever since then, the removal efficiency has remained between 90% and 95%, with higher efficiencies recorded occasionally. Since the initial start-up period, the H2S removal efficiency has never fallen below 90%.5 This is in a small trickling biofilter with less than 10 seconds of residence time.

Parametric studies aimed at optimizing the operating conditions are now under way, and will be reported in a future paper. However, the consistent performance of this test unit over a period of months has demonstrated conclusively that the proper environment for Thiobacillus growth can be maintained using HD Q-PAC® and extremely simple equipment.

FB

FB

0 Comments