Latest Downloads

-

Water Bath Indirect Heaters

Water Bath Indirect HeatersArt Montemayor - Oct 12 2018 02:35 PM

-

Petroleum: A Primer for Kansas

Petroleum: A Primer for KansasArt Montemayor - Oct 12 2018 02:27 PM

-

Spray Tower for Flue Gas Scrubbing Design

Spray Tower for Flue Gas Scrubbing Designankur2061 - May 02 2018 02:31 PM

-

Selection of Vertical Tanks

Selection of Vertical Tanksankur2061 - Apr 19 2018 07:42 AM

-

Pressure Drop Calculator for Strainers 1

Pressure Drop Calculator for Strainers 1ankur2061 - Mar 24 2017 02:04 PM

-

Horizontal Pig Trap System Design Guidelines

Horizontal Pig Trap System Design Guidelinesankur2061 - Jan 14 2017 02:54 PM

-

Performance Prediction of 3-Stage Propane Refrigeration System

Performance Prediction of 3-Stage Propane Refrigeration Systemankur2061 - Aug 08 2016 02:43 PM

-

Centrifugal Pump Troubleshooting Checklist

Centrifugal Pump Troubleshooting Checklistankur2061 - Dec 17 2015 08:18 AM

-

Compressor Troubleshooting Checklist

Compressor Troubleshooting Checklistankur2061 - Sep 08 2015 11:43 AM

-

Amine Sweetening Unit Preliminary Design

Amine Sweetening Unit Preliminary Designankur2061 - May 19 2015 09:35 AM

Popular Store Titles

Tank Jacket Calculator

Tank Jacket Calculator

Specification Sheet Collection

Specification Sheet Collection

PIPESIZE

PIPESIZE

Relief Valve Sizing

Relief Valve Sizing

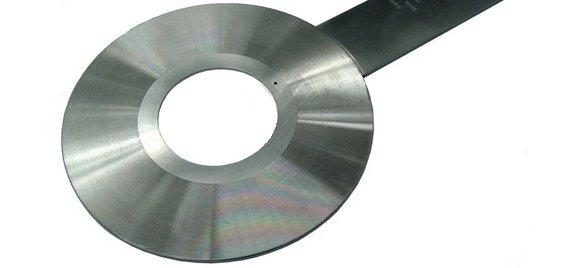

Rupture Disc Sizing

Rupture Disc Sizing

Chemical and Process Engineering Resources

Safety and Pressure Relief

Flow Through Orifice Plates in Compressible Flu...

Nov 08 2010 01:40 PM |

dkirk

in Safety and Pressure Relief

The calculation of compressible flow through orifice plates at high dP (critical flow) appears to be carried out incorrectly in most instances. This flow condition is often encountered on gas plants, compressor stations and pipelines where orifice plat...

Read story → 0 comments

Tank Blanketing Basics Covered

Nov 08 2010 01:40 PM |

proinwv

in Safety and Pressure Relief

Tank blanketing, or padding, refers to applying a cover of gas over the surface of a stores commodity; usually a liquid. Its purpose is either to protect or contain the stored product or prevent it from harming personnel, equipment, or the environment....

Read story → 2 comments

Relieve Valve Set Pressures

Nov 08 2010 01:20 PM |

pleckner

in Safety and Pressure Relief

As the title of this column implies, I intend to present various topics related to Process Engineering Design based on my knowledge and experiences. I will convey what approaches I think you should be taking. I will stress "the correct way" so don't ex...

Read story → 0 comments

Pyrophoric Iron Fires

Nov 08 2010 01:30 PM |

Mukesh Sahdev

in Safety and Pressure Relief

At one time or another, most refineries experience spontaneous ignition of iron sulfide either on the ground or inside equipment. When this occurs inside equipment like columns, vessels, and tanks and exchangers containing residual hydrocarbons and air...

Read story → 1 comments

Rupture Disks for Process Engineers - Part 6

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. Part 3 discussed how to set the burst pressure. Part 4 discussed...

Read story → 0 comments

Rupture Disks for Process Engineers - Part 5

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. Part 3 discussed how to set the burst pressure. Part 4 discussed...

Read story → 0 comments

Rupture Disks for Process Engineers - Part 4

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. Part 3 discussed how to set the burst pressure. In this part, I w...

Read story → 0 comments

Rupture Disks for Process Engineers - Part 3

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. In this part, I will cover how to set the burst pressure. Subsequ...

Read story → 0 comments

Rupture Disks for Process Engineers - Part 2

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. This part will discuss how to size the rupture disk. Subsequent parts will include how to set the burst pressure...

Read story → 0 comments

Rupture Disks for Process Engineers - Part 1

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

This is a real story. A rupture disk manufacturer presented a seminar to a group consisting of junior and more senior level process design engineers (yours truly included) with a few instrument engineers thrown in. After about an hour of hearing terms...

Read story → 1 comments

Relief Valves: "What Can Go Wrong" Scen...

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

What can go wrong in a chemical facility? Plenty! A report in the August 2000 issue of CEP1 shows that operator error or poor maintenance was the leading of cause of accidents for unfired pressure vessels eight years running. The ProblemAccidents not o...

Read story → 0 comments

FB

FB