i have one questine in the exchanger condensate line operation

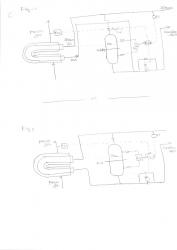

the process diagram is like in fig 1

1. what happen if we connect the condensate like in first case

2. what happen if we connect the condensate like in the second case( most shell and tube exchanger has like case)

the steam inlet pressure is 17kg/cm2

FB

FB