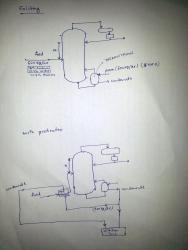

Refer to the attached drawing for more details .

In this distillation column acetone is to be separated from a mixed feed coming at ambient temperature. It is a packed column with mellapack packings. Steam is used in the reboiler (thermo syphon) for heating. Details of these streams are

Feed: 600 kg/hr (72% acetone, 17.5% water & 10.5% aniline)

Steam: 600 kg/hr, 3 bar-g

Boiling point of acetone is 56 degC. I want to use the steam condensate coming from the reboiler for preheating the feed upto acetone boiling point(without vaporization).From the calculations it comes out ~203kg/hr of condensate is required and a plate heat exchanger can be used for this.

But since I have 500 kg/hr condensate available, it can be used to vaporize the feed to some extent.

Questions:

1. How do we enter the partially vaporized feed into the column i.e. will any changes be required in the existing piping and pumping system.

2. Location of PHE: should it be kept below reboiler level to avoid flooding of reboiler or 3 barg pressure is sufficient to have continuous flow.

3. Location of feed tray: since the feed is near saturation or vaporized w.r.t acetone, I thing feed tray location can be lowered further(refer pic. y>x) and it might increase the product purity as well.

FB

FB