Hello,

I am working in a team trying to do a mass balance for a sugar refinery. The units consist mainly of affination, clarification, decolorization, crystallization, and drying. We have been given the required output specifications (in terms of pol, invert, ash etc) and the output flowrate. We have started to work out the mass balance backwards. So far, we have been using typical values as assumptions.

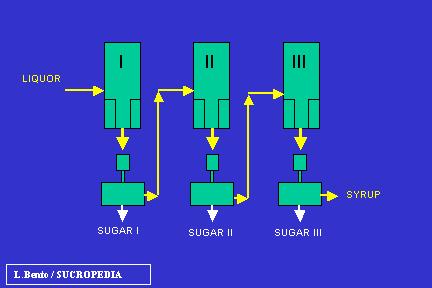

But we have been facing some problems with the crystallization part...

There are 3 sugars coming out of 3 centrifuges and a final molasse.

We have not been able to find out how the values are affected in each of the set of vacuum pans, mixer and centrifuges(there are 3 set). Could you kindly advice on how we can proceed.

Thanking you in advance

FB

FB