Typically, plate and frame heat exchangers are used for liquid-liquid exchange at low to medium pressures. However, gasket-free plate and frame heat exchangers can safely operate at high temperatures and pressures. Plate and frame heat exchangers offer flexibility because plates can be either added or compressed for each different situation.

The gaps between the plates in plate and frame heat exchangers can be adjusted according to the degree of fouling (deposits, corrosion, etc.) that is expected.

The counter-current flow of fluids that occurs in plate and frame heat exchangers allows approach temperatures as low as 1 to 2°F.

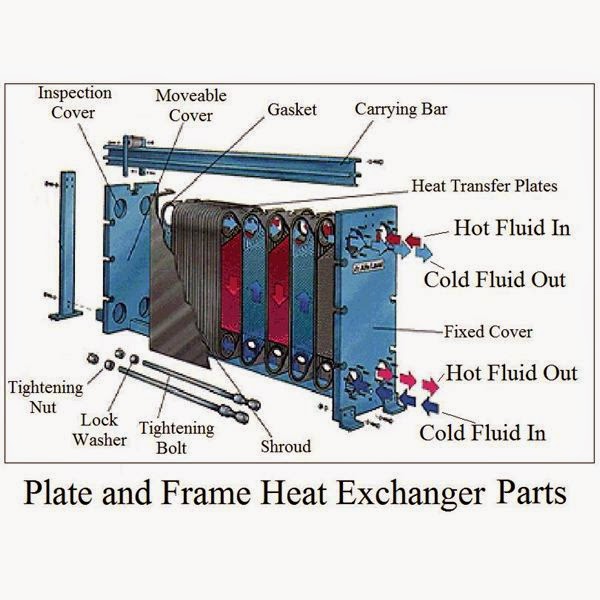

Gaskets ensure that the cold fluid (blue) and the hot fluid (red) don't mix. Alternatives to the traditional gasket seal include brazing and laser-welding.

The plates are stacked in an alternating manner to cause the counter current flow. The diagram below shows the flow in a heat exchanger. The design allows for the two media to flow in alternate directions and not be mixed. However, heat can be transferred from one medium to the other through the plates.

- Require less space and are less expensive than shell and tube heat exchangers.

- Easy to adjust for different liquids by adding or subtracting plates.

- Pressure can be varied by compressing the plates.

- One frame can be used for multiple duties by simply changing plates.

- Working temperatures up to 550°C and pressures of 780 psi are possible with gasket-free versions.

- High heat transfer coefficientsrelative to shell and tube heat exchangers.

- Up to ten times more resistant to fouling than shell and tube heat exchangers.

- Gasketed plate and frame heat exchangers have a maximum operating condition of 149°C and 300 psi.

- Not good for vaporizing fluids or large amounts of vapor.

- Gasket-free versions are impossible to open for inspection or cleaning.

FB

FB