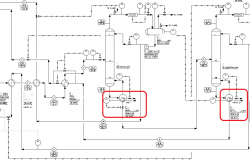

If it is working, I should ignore this PFD, because some of the controls won't work as shown. You should provide the requested residence time on the outlet side of the reboiler weir. So, just extend the shell beyond that calculated with HTRI. What is the source of the feed to the unit? You client would be well advised to have some knowledgeable engineer review the controls and other things. Operations could be greatly improved. What is the capacity of the unit? And the isobutane is sold as product?

The column pressure control as shown can only work by flooding the condenser. So, the liquid temperature cannot be controlled as shown. Reboil control is best accomplished with a lower tray temperature, not the reboiler outlet temperature.

Bobby

Edited by Bobby Strain, 26 February 2024 - 05:47 PM.

FB

FB