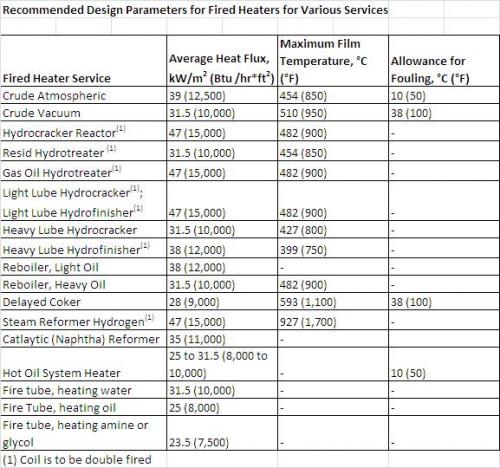

Today I was going through some write-up related to fired heaters from old manuals of a world-class operations company and found some very good information related to "Heat Flux" and "Maximum Film Temperature" for fired heaters used in various services. Although process design engineers working for general engineering consulting firms could never think of designing a fired heater on their own, one of the most common activity related to fired heaters would be the preparation of a process data sheet for a fired heater by a process engineer. Data such as average and peak heat flux and maximum film temperature would be required to be filled in the datasheet for a fired heater.

Today I was going through some write-up related to fired heaters from old manuals of a world-class operations company and found some very good information related to "Heat Flux" and "Maximum Film Temperature" for fired heaters used in various services. Although process design engineers working for general engineering consulting firms could never think of designing a fired heater on their own, one of the most common activity related to fired heaters would be the preparation of a process data sheet for a fired heater by a process engineer. Data such as average and peak heat flux and maximum film temperature would be required to be filled in the datasheet for a fired heater.Before going into the figures for heat flux and maximum film temperature it is important to understand what these terms mean in context to a fired heater.

In general heat flux is the main determinant for the tube area of a fired heater. It has the units kW / m2 in SI units and Btu / hr*ft2 in English units. It is the rate of heat transmission through the tubes into the process fluid. The area used in the specification of heat flux is usually the outside tube area in the radiant section. Heat flux can be classified as the average heat flux and the peak heat flux for a fired heater.

Average Heat Flux

The average flux is obtained by dividing the duty of the radiant section by the total exposed outside tube area. This approach is valid for "well-mixed" fireboxes where there is little variation of flue gas temperature throughout the box. (Steam reformer heaters in hydrogen, ammonia and methanol plants are an important exception).

If the flux is too high in the radiant section of an existing heater, the only way to decrease it is by reducing the firing rate.

Peak or Maximum Heat Flux

Suppose a bank of tubes, with a center-to-center spacing of two tube diameters, is placed one or two tube diameters away from a refractory wall and is uniformly fired from the opposite side of the wall then the side of the tube facing the flame will receive direct radiation and the opposite side will receive radiation reflected from the wall. The hottest point on the tube will be on the side facing the flame where the surface is at a right angle to the flux. This is the peak or maximum heat flux and it will be about 1.8 times the average value.

When the bank of tubes is placed in the center of the firebox and is fired uniformly from two sides, the ratio of peak to average flux will be 1.2. This illustrates the advantage of two-sided or double firing. Thus for a given peak flux, the average flux will be 50% greater than in the case of single or one-sided firing.

For most fired heater applications the peak flux values are in the range of 47 to 69 kW/m2 (15,000 to 22,000 Btu/hr*ft2) and average flux values are in the range of 25 to 47 kW/m2 (8,000 to 15,000 Btu/hr*ft2). Refer the attached table for average heat flux values.

Maximum Inside Film Temperature

Flux, either peak or average, is a useful parameter to fix when specifying a fired heater for design. Excessively high flux will cause tube overheating and even lead to damage of the heater refractory walls. But what is really of concern from the process view point is the maximum inside fluid film temperature. This is the maximum temperature that the fluid sees.

The maximum temperature difference across the inside film can be calculated as the peak flux (adjusted to the basis of the inside tube area) divided by the inside (convective) heat transfer coefficient. This difference when added to the maximum process bulk temperature provides the maximum film temperature. Recommended maximum film temperatures for some applications are provided in the attached table. Inside heat transfer coefficients range from a minimum of 0.11 kW/m2*K (20 Btu/ft2*h*degF) for gases up to approximately 5.7 kW/m2*K (1000 Btu/ft2*h*degF) for boiling water (steam generation).

Fouling

For heaters with with tubes known to be subject to inside fouling, the process engineer may specify a temperature allowance for fouling. This temperature difference is added to the maximum inside film temperature to get the inside tube metal temperature. It will affect the mechanical design of the tubes. Temperature allowances are in the range of 10 to 38 deg C (50 to 100 deg F). Refer the attached table.

So that is about it for heat flux and maximum film temperature for fired heaters. The table attached for recommended values is the recommendation of a particular company. These values may be different based on design and operating experience of another company and hence I advise the engineers to verify the figures for suitability to the fired heater design objectives of any other company for which they are providing the data.

Hoping to have some comments on this entry from the readers of my blog.

Regards,

Ankur.

FB

FB

I really appreciate that you take time and write these beneficial article for young engineer like us.