Dear all members:

I was assigned a BEU type condenser rating work, but I found the HTRI result seems a little bit wired.

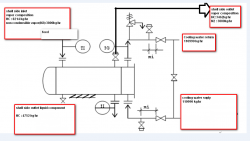

Parameters given by client are below:

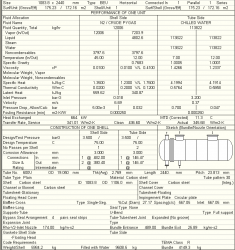

This type of condenser is BEU type and Horizontal, and I have tried using HTRI rating mode to set Single-segmental baffles, 4 cross pass, tube length = 2440mm.

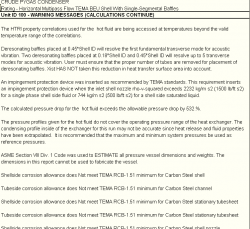

But, the pressure drop in shell side still always greater than allowable pressure drop (0.005 bar) in shell side, even if I increase the shell id to 1056 mm.

I also tried double-segmental baffles so that the pressure drop could be much smaller than that in shell wiht signle-segmental baffles, but unfortunately,

the pressure drop is still greater than allowable pressure drop. By the way, I tried use design mode in HTRI and there is a good convergence result in HTRI.

(The pressure drop in shell is in allowable range). But, our leader is not accepted this design mode result since the baffle cut ratio is optimizing automatically by HTRI.

I was wondering this BEU type given by client seems wrong, because TEMA J shells are most typically specified for this phase change duties where significantly reduce shell side pressure drop are required. They are commonly used with a single nozzle as inlet and two nozzle as outlet, for vapor and liquid separate better. Please justify and give any suggest about my deduction and calculation result.

Thank you so much.

Best regards,

FB

FB