This sounds simple but i need some clarifications. I am using a hot plate to heat a solution in an oil bath. The power rating and maximum temperature of the hot plate is 1520 W and 500 oC respectively. I set the hot plate temperature to 140 oC based on my experiment. How can i determine the exact/near exact power output (W) of the hot plate at 140 oC?

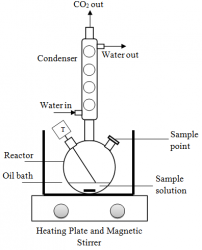

I attached the sample set-up.

FB

FB