Hello All,

I am currently working to modify an existing boiler feed water tank to bitumen service. The project has just finished DBM and I am trying to get a better handle on the tank heat transfer prior to FEED.

The bitumen will need to maintained at 90 degC, the existing tank is already insulated and heat loss calculations have been completed. If the temperature falls below 90 deg C the product will become very viscous and difficult to pump out. I need to ensure that the new design will adequately mix the product (by means of recirculation) and heat the product (with the new chromalox immersion type heater).

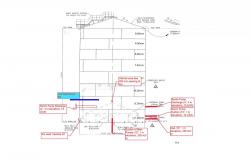

Modifications to the tank currently include addition of:

1. Inlet (250 m3/hr)

2. Outlet to booster pumps – (250 m3/hr)

3. Recirculation pump suction (10 m3/hr)

4. Recirculation pump discharge back into tank (10 m3/hr)

5. Heating Element

Please find a sketch for the proposed nozzle locations, size and elevation.

The recirculation loop will always be on at 10 m3/hr. The heater is designed for maximum heat losses during winter conditions. Basically, as the level in the tank rises the pumps will turn on and pump out to the low liquid level.

The proposed heater is an electric immersion type heater (http://www.chromalox...es/im-pn403.pdf) due to the low installation fees. The pipe size is 14” with an immersion length of 4.5 m (not even halfway into the tank).

I have never used this type of tank heater before – does anyone have experience with this type of heater? Is there anything I should be aware of?

I will be speaking with the heater vendor to gain additional insights in parallel to this forum request.

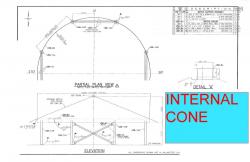

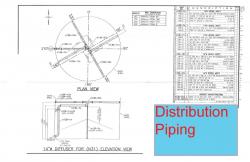

The existing tank has some internals that I am afraid may interfere with the process and thorough heating of the fluid:

· Inlet distribution piping

· Internal raised cone

The attached drawing shows the elevation of the cone. I am wondering what impact the vessel internals will have on the process.

If the immersion heater is located near the cone (within 200 mm) will there be an issue? Will the cone affect the heat transfer throughout the fluid? Should I be getting CFD completed to confirm there is no issue?

As far as piping within the vessel (distribution piping) – in order to avoid stagnant points in the tubes, should I blank these off on the inside of the vessel? Or would it be worthwhile just to remove this piping all together?

Thank you for your help with this problem, I will be happy to provide any additional information as required.

FB

FB