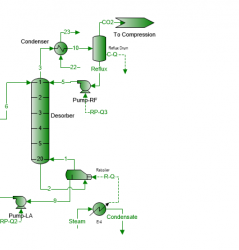

Could you please explain how it is that you expect a pressure drop to exist in the shell side of a kettle reboiler?

Doesn't your solution enter the shell side of the reboiler as over flow from the bottom of your stripper, flow laterally through the length of your tube bundle via convection currents until it reaches a weir that allows for overflow of the same liquid? While this procedure is happening the upper space of the kettle (shell side) is filled with stripping vapor AT THE SAME PRESSURE THROUGHOUT THE LENGTH OF THE KETTLE.

The reason the shell side liquid "flows" from one end of the kettle to the other is because it falls by gravity into the shell, fills the tube bundle section of the reboiler and rises in level as it fills that section up to the weir's height, where it falls by gravity into the weir's downstream section to be sucked by the suction of the rich solution pump.

I believe under the above described conditions the "pressure drop" across the length of the kettle's internal liquid space is essentially ZERO. Please correct me if my description and response are wrong, but that is the logic I've always used in designing and building my kettle reboilers in the past.

FB

FB