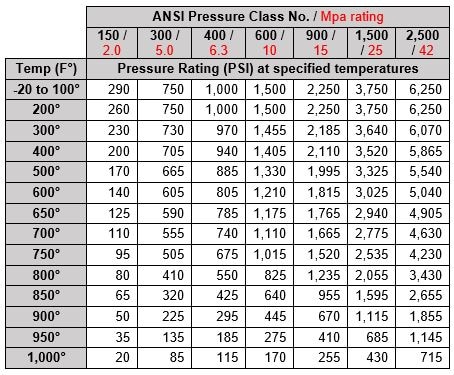

hello sirs. I did a training in a chemical plant refinery recently. I could see that the pipe has asme rating which is 150, 300 etc. I also saw some tables in asme b16.5 showing pressure and temp. rating of this classes. is the meaning of this classes that the pipe of 300 class is good for that pr. and temp.? or is it means something else. Also, is design pressure based on the class...if 300 class and the design temp. pr from the b16.5 table? please comment.

thanks, onakr

FB

FB