Hi Dear Engineers,

I'm reaching out for your support in understanding a recurrent issue with cyclic steam pressure pulsations.

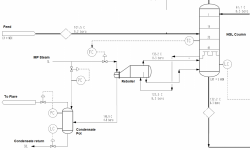

We have a reboiler installed at the bottom of the NGL column that use MP steam as a heating medium. The reboiler vapor return temperature is controlled by a steam flow control valve. The condensed steam is routed to a condensate pot where the pressure is controlled by pressure control valve using also the MP steam. The pot is also equipped with a level control valve.

The concern:

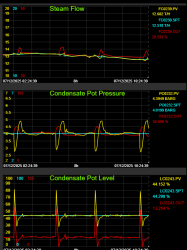

We are experiencing a cyclic pressure pulsation in the condensate pot causing a mild intermittent hammering even though the column operation is steady and no operating parameters are changing.

Any insight or technical guidance to help me understand the root cause would be highly appreciated.

Thank you in advance for your support.

N.B: I have attached a DSC screenshot and the process PFD for more clarity.

FB

FB