Chemical and Process Engineering Resources

Perceptible indications of the cavitation during pump operation are more or less loud noises, vibrations and an unsteadily working pump. Fluctuations in flow and discharge pressure take place with a sudden and drastic reduction in head rise and pump capacity. Depending upon the size and quantum of the bubbles formed and the severity of their collapse, the pump faces problems ranging from a partial loss in

A detailed description of the general symptoms is given as follows.

Reduction in Capacity of the Pump

The formation of bubbles causes a volume increase decreasing the space available for the liquid and thus diminish pumping capacity. For example, when water changes state from liquid to gas its volume increases by approximately 1,700 times. If the bubbles get big enough at the eye of the impeller, the pump "chokes" i.e. loses all suction resulting in a total reduction in flow. The unequal and uneven formation and collapse of bubbles causes fluctuations in the flow and the pumping of liquid occurs in spurts. This symptom is common to all types of cavitations.

Decrease in the Head Developed

Bubbles unlike liquid are compressible. The head developed diminishes drastically because energy has to be expended to increase the velocity of the liquid used to fill up the cavities, as the bubbles collapse. As mentioned earlier, The Hydraulic Standards Institute defines cavitation as condition of 3 % drop in head developed across the pump. Like reduction in capacity, this symptom is also common to all types of cavitations.

|

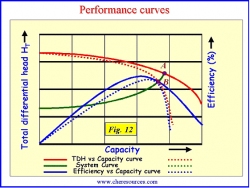

| Figure 12: Pump Performance Curves |

Thus, the hydraulic effect of a cavitating pump is that the pump performance drops off of its expected performance curve, referred to as break away, producing a lower than expected head and flow. The Figure 12 depicts the typical performance curves. The solid line curves represent a condition of adequate NPSHa whereas the dotted lines depict the condition of inadequate NPSHa i.e. the condition of cavitation.

Abnormal Sound and Vibration

It is movement of bubbles with very high velocities from low-pressure area to a high-pressure area and subsequent collapse that creates shockwaves producing abnormal sounds and vibrations. It has been estimated that during collapse of bubbles the pressures of the order of 104 atm develops.

The sound of cavitation can be described as similar to small hard particles or gravel rapidly striking or bouncing off the interior parts of a pump or valve. Various terms like rattling, knocking, crackling are used to describe the abnormal sounds. The sound of pumps operating while cavitating can range from a low-pitched steady knocking sound (like on a door) to a high-pitched and random crackling (similar to a metallic impact). People can easily mistake cavitation for a bad bearing in a pump motor. To distinguish between the noise due to a bad bearing or cavitation, operate the pump with no flow. The disappearance of noise will be an indication of cavitation.

Similarly, vibration is due to the uneven loading of the impeller as the mixture of vapor and liquid passes through it, and to the local shock wave that occurs as each bubble collapses. Very few vibration reference manuals agree on the primary vibration characteristic associated with pump cavitation. Formation and collapsing of bubbles will alternate periodically with the frequency resulting out of the product of speed and number of blades. Some suggest that the vibrations associated with cavitation produce a broadband peak at high frequencies above 2,000 Hertz. Some suggest that cavitation follows the vane pass frequency (number of vanes times the running speed frequency) and yet another indicate that it affects peak vibration amplitude at one times running speed. All of these indications are correct in that pump cavitation can produce various vibration frequencies depending on the cavitation type, pump design, installation and use. The excessive vibration caused by cavitation often subsequently causes a failure of the pump's seal and/or bearings. This is the most likely failure mode of a cavitating pump,

Damage to Pump Parts

Cavitation Erosion or Pitting

|

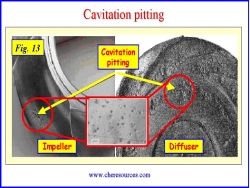

| Figure 13: Photographic Evidence of Cavitation |

During cavitation, the collapse of the bubbles occurs at sonic speed ejecting destructive micro jets of extremely high velocity (up to 1000 m/s) liquid strong enough to cause extreme erosion of the pump parts, particularly impellers. The bubble is trying to collapse from all sides, but if the bubble is lying against a piece of metal such as the impeller or volute it cannot collapse from that side. So the fluid comes in from the opposite side at this high velocity and bangs against the metal creating the impression that the metal was hit with a "ball pin hammer". The resulting long-term material damage begins to become visible by so called

Pits (see Figure 11), which are plastic deformations of very small dimensions (order of magnitude of micrometers). The damage caused due to action of bubble collapse is commonly referred as Cavitation erosion or pitting. The Figure 13 depicts the cavitation pitting effect on impeller and diffuser surface.

Cavitation erosion from bubble collapse occurs primarily by fatigue fracture due to repeated bubble implosions on the cavitating surface, if the implosions have sufficient impact force. The erosion or pitting effect is quite similar to sand blasting. High head pumps are more likely to suffer from cavitation erosion, making cavitation a "high-energy" pump phenomenon.

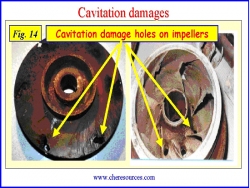

The most sensitive areas where cavitation erosion has been observed arethe low-pressure sides of the impeller vanes near the inlet edge. The cavitation erosion damages at the impeller are more or less spread out. The pitting has also been observed on impeller vanes, diffuser vanes, and impeller tips etc. In some instances, cavitation has been severe enough to wear holes in the impeller and damage the vanes to such a degree that the impeller becomes completely ineffective. A damaged impeller is shown in Figure 14.

|

| Figure 14: Cavitation Damage on Impellers |

The damaged impeller shows that the shock waves occurred near the outside edge of the impeller, where damage is evident. This part of the impeller is where the pressure builds to its highest point. This pressure implodes the gas bubbles, changing the water's state from gas into liquid. When cavitation is less severe, the damage can occur further down towards the eye of the impeller. A careful investigation and diagnosis of point of the impeller erosion on impeller, volute, diffuser etc. can help predict the type and cause of cavitation.

The extent of cavitation erosion or pitting depends on a number of factors like presence of foreign materials in the liquid, liquid temperature, age of equipment and velocity of the collapsing bubble.

Mechanical Deformation

Apart from erosion of pump parts, in bigger pumps, longer duration of cavitation condition can result in unbalancing (due to un-equal distribution in bubble formation and collapse) of radial and axial thrusts on the impeller. This unbalancing often leads to following mechanical problems:

- bending and deflection of shafts,

- bearing damage and rubs from radial vibration,

- thrust bearing damage from axial movement,

- breaking of impeller check-nuts,

- seal faces damage etc.

These mechanical deformations can completely wreck the pump and require replacement of parts. The cost of such replacements can be huge.

Cavitation Corrosion

Frequently cavitation is combined with corrosion. The implosion of bubbles destroys existing protective layers making the metal surface permanently activated for the chemical attack. Thus, in this way even in case of slight cavitation it may lead to considerable damage to the materials. The rate of erosion may be accentuated if the liquid itself has corrosive tendencies such as water with large amounts of dissolved oxygen to acids.

Cavitation- The Pump Heart Attack

Thus fundamentally, cavitation refers to an abnormal condition inside the pump that arises during pump operation due to formation and subsequent collapse of vapor filled cavities or bubbles inside the liquid being pumped. The condition of cavitation can obstruct the pump, impair performance and flow capacity, and damage the impeller and other sensitive components. In short, Cavitation can be termed as "the heart attack of the pump".

FB

FB

12 Comments

Great article but in your classification of pump problems, you have left out the most important class., i.e. problems in getting required parameters because of system conditions.Design Problems is of little use to the site engineer as he can't do anything about it. He can definitely correct system problems however.

Hii

I have a question regarding centrifugal pump.

A new pump is under commssioning in my plant and we have to go for water trial, can you please provide details on that how to proceed?

Great... thank u,,,,

THE BEST ONE...........

Thanks a lot ; it is much better than any other text about this topic in the pump literature , thanks again