Pipeline Surge has been a hotly debated topic on "Cheresources". During one of these discussions I had said that I would try to compile a blog entry related to pipeline surge possibly with an excel workbook. Today's blog entry discusses pipeline surge sans the excel workbook. I expect the young process engineers to develop their own spreadsheet from this blog entry. What I am going to discuss is the fundamentals related to pipeline surge which also form part of the excel workbook I created for pipeline surge, as explanatory notes on the phenomena of surge. Let us begin:

Pipeline Surge has been a hotly debated topic on "Cheresources". During one of these discussions I had said that I would try to compile a blog entry related to pipeline surge possibly with an excel workbook. Today's blog entry discusses pipeline surge sans the excel workbook. I expect the young process engineers to develop their own spreadsheet from this blog entry. What I am going to discuss is the fundamentals related to pipeline surge which also form part of the excel workbook I created for pipeline surge, as explanatory notes on the phenomena of surge. Let us begin:Pressure Surges:

- Pressure surges in a pipeline are created by a change in momentum of the moving stream, e.g. by closing a valve, the origin of the pressure surge being at the point where the momentum of flow is changed.

- Because of the low density of gases compared to liquids, pressure surges are not of concern in gas lines.

- The theoretical maximum pressure surge that can be created in a pipeline would be caused by an instantaneous total blockage of the flow and would occur at the point of flow retardation, e.g. the valve.

- The maximum surge pressure is the sum of two components:

(i) The instantaneous pressure increase at the moment of total flow blockage

(ii) The subsequent gradual pressure rise due to the 'line packing' effect.

The magnitude of the instantaneous surge can be calculated using Joukowsky's equation:

Ps = ρ*a*Δv

where:

Ps = surge pressure, Pa

ρ = liquid density, kg/m3

a = pressure wave velocity, m/s

Δv = velocity change, m/s

The wave velocity "a" is given by:

a = square root(1 / ((1/K + (d/tw)*(1/E))*ρ))

where:

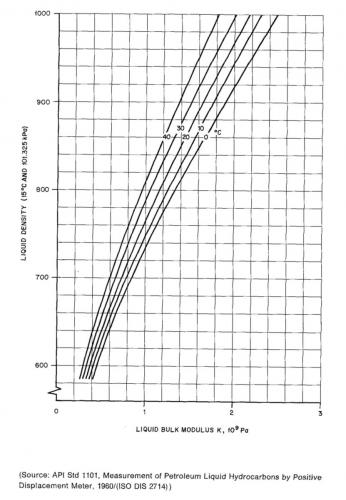

K = Liquid Bulk Modulus (refer attachment); water bulk modulus is generally considered as 2.2*109 Pa

d = pipe internal diameter, m

tw = pipe wall thickness, m

E = Young's modulus of pipe material, Pa (for commercial steel it is considered as 210*109 Pa)

Methods of Reducing Surge Pressure:

The primary method of preventing the generation of unacceptably high surge pressures should be the implementation and strict adherence to well formulated and clearly written operating procedures. Additional measures which may be employed to reduce surge pressures are as follows:

1. Slow Valve Closure:

By closing a valve over a sufficiently long period the surge generated may be significantly reduced. This also allows more time to trip the pumps and hence reduce the maximum pressure. This can be implemented either by slowing down the valve actuator or by installing a two speed actuator which reduces the valve closure speed over the (critical) last 10-20% of the valve's travel.

2. Installing a Pressure Relief System:

If the creation of an unacceptable pressure surge cannot be avoided using option 1, a pressure relief system can be installed as near to the point of surge origin as practically possible. The system would vent a quantity of product from the pipeline once a pre-set pressure limit is exceeded thereby limiting the final surge pressure. This can be implemented using bursting discs or rapid response relief valves.

3. Installing a Pump Trip:

If the advent of a potentially dangerous pressure surge is detected early enough, the tripping of the upstream pumps will generate a negative pressure wave which propagates from the pumps to the origin of the surge and can counter the positive pressure surge. The effectiveness of this form of surge protection depends on factors such as the pipeline length, amount of line packing, etc.

Readers of my blog, hope you enjoy this blog entry and I look forward to your comments.

Regards,

Ankur.

FB

FB

Install a rapid response relief valve or Rupture Disk downstream of the angle stop valve to mitigate this problem.

Another way of mitigating this problem would be to provide non-slam check valves at the pump discharge to prevent damage due to pressure surge. Some links are provided below:

http://www.eng-tips.....cfm?qid=336042

http://www.eng-tips.....cfm?qid=111189

http://www.valmatic....heckvalves.html

Hope this helps.

Regards,

Ankur