Selection And Sizing Of Marine Loading Arms For Petroleum (Black / White Oil) Products

Dear All,

Dear All,Todya's blog entry provides a procedure for selection / sizing of marine loading arms

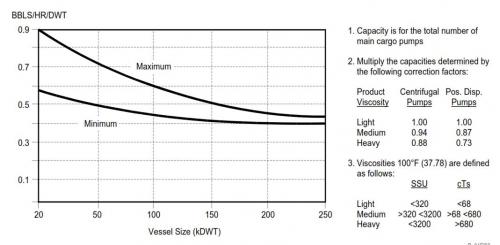

Vessel / Tanker Design Discharge Capacity (Figure 1)

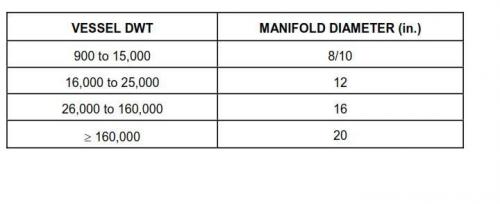

Oil Tanker Manifold Diameters

Loading Arm size should not be larger than a maximum of two sizes of the the ships manifold diameter. A smaller size loading arm compared to the ship's manifold diameter is acceptable using a reducing spool piece.

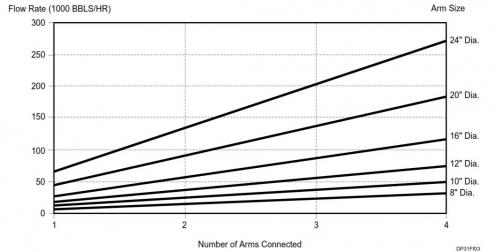

Flow Rate Vs No. of Marine Loading Arms (Figure 2)

Based on limiting flow velocity of 11 m/s (36 ft/s)

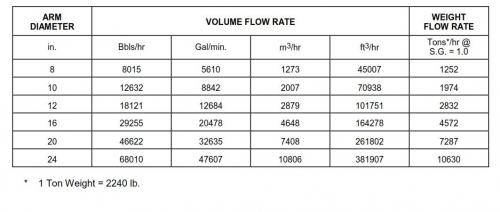

Maximum Marine Arm Loading Flow Rates

Based on Limiting Flow Velocity of 11 m/s (36 ft/s)

Example Calculation

Inputs

Max Vessel Size = 100,000 DWT

Product Viscosity = Heavy

Pump Type = Centrifugal

Outputs

bbls/hr/DWT = 0.6 (From Figure1)

Correction factor = 0.88

Max. Discharge Rate = 52,800 bbls/hr

Max. Arm Size = 16 inch

No. of Arms = 2 (From Figure 2)

Note:

Part III, Section 2-Guidelines (page 40) of the document "Design & Construction Specification for Marine Loading Arms" which is issued as a standard for MLAs by the "Oil Comapnies and International Marine Forum" with the acronym "OCIMF" recommends a maximum velocity of 12 m/s through marine loading arms.

Looking forward to hear comments from the members of the "Cheresources" community.

Regards,

Ankur.

FB

FB

Hi Ankur; nice selection of topic to share.

We are searching guidelines for nitrogen purging of MLA in case of emergency trip by ESD-2 and after trip how much time shall be kept in margin to reconnect the MLA again after nitrogen purging?

If you can comment on it; will glad to listen it.