Dear Experts,

For relief load calculation, I need to know amount of reboiler duty getting used in vaporizing the liquid.

For that I am following two approaches:

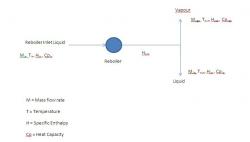

Approach 1: Multiplying the difference in specific enthalpy of reboiler outlet vapor stream and reboiler inlet liquid steam with the mass flow rate of reboiler outlet vapor stream.

Approach 2: Calculating the amount of heat going in the reboiler outlet liquid stream using MCpΔT method, where M is the reboiler outlet liquid stream flow rate, Cp is the average Cp of reboiler inlet liquid and reboiler outlet liquid and ΔT is the temperature difference in the reboiler inlet and outlet stream.

Both the approaches are giving different results.

It seems that the error in approach 1 might be due to composition difference between reboiler inlet liquid and outlet vapor. (Not sure about it).

Could you please help me in finding the right approach and suggest the conceptual mistake that I am making here?

Thanks in advance !!

Regards,

Arpit Jain

FB

FB