Dear all,

My name is Yogan Felipe Sganzerla, and I am a Mechanical Engineer, writing from Brazil.

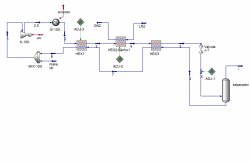

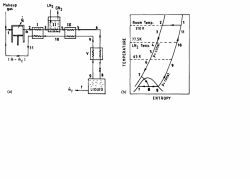

I am simulating a Linde-Hampson Cycle to liquefy hydrogen. The cycle is as shown in the attached photo. Additionally, I am adding a photo of my simulation.

You can find the .hsc file at this link (my Google Drive): https://drive.google...ew?usp=sharing.

Let me talk a little bit more about our trouble...

I need to define the maximum effectiveness of the HEX2 - bath so that the minimum approach is higher than zero (as close as possible to zero). For example, when I have in the stream LN2 10% of N2 and 90% of methane (set in spreadsheet composition), the temperature cross appears, and it is because in my ADJ-2, the Specific Target Value is 0.98 (effectiveness), meaning that it is too high for this mixture, so I should decrease it. I would like to do it automatically because I will run many scenarios for compositions.

How can I implement this?

Thank you for your attention, and if you need additional information, just let me know.

Kind regards,

FB

FB