Articles Archives

Understanding Compressible Flow

Nov 08 2010 01:40 PM |

rxnarang

in Fluid Flow

Understanding the flow of compressible fluids in pipes is necessary for a robust design of process plants. The main difference between incompressible fluid, like water, and compressible fluid, vapor, is the greater change in pressure and density. This...

Article Images:

Read story →

0 comments

Forms of Corrosion

Nov 08 2010 01:20 PM |

Chris Haslego

in Maintenance and Repair

Corrosion is costly! If you doubt this, then you probably have never been bitten by the "corrosion bug". Imagine specifying Titanium for 10 brand new heat exchangers or reactors and later realizing that the processing stream has fairly high concentra...

Article Images:

Read story →

2 comments

Crystallization

Nov 08 2010 01:30 PM |

Chris Haslego

in Separation Technology

Crystallization refers to the formation of solid crystals from a homogeneous solution. It is essentially a solid-liquid separation technique and a very important one at that. Crystals are grown in many shapes, which are dependent upon downstream proc...

Article Images:

Read story →

0 comments

Using Equivalent Lengths of Valves and Fittings

Nov 08 2010 01:20 PM |

pleckner

in Fluid Flow

One of the most basic calculations performed by any process engineer, whether in design or in the plant, is line sizing and pipeline pressure loss. Typically known are the flow rate, temperature and corresponding viscosity and specific gravity of the f...

Article Images:

Read story →

3 comments

Estimating Heat Capacities for Solutions with D...

Nov 08 2010 01:40 PM |

Chris Haslego

in Calculations and Tips

Often times it is necessary to find the heat capacity for solutions with dissolved solids. A quick estimation method was proposed by Dimoplon in 1972. The proposed expression is:Cp(soln) = W1 Cp(solid) + W2 Cp(water)Eq. (1)where:Cp(soln) = Heat capacit...

Article Images:

Read story →

1 comments

Flow Through Orifice Plates in Compressible Flu...

Nov 08 2010 01:40 PM |

dkirk

in Safety and Pressure Relief

The calculation of compressible flow through orifice plates at high dP (critical flow) appears to be carried out incorrectly in most instances. This flow condition is often encountered on gas plants, compressor stations and pipelines where orifice plat...

Article Images:

Read story →

0 comments

Making Decisions with Insulation

Nov 08 2010 12:30 PM |

Chris Haslego

in Heat Transfer

Many people overlook the importance of insulation in the chemical industry. Some estimates have predicted that insulation in U.S. industry alone saves approximately 200 million barrels of oil every year. While placing insulation onto a pipe is fairly...

Article Images:

Read story →

2 comments

U in Heat Exchangers

May 10 2012 08:19 AM |

bspang

in Heat Transfer

Typical values of U are useful for quickly estimating the required surface area. The literature has many tabulations of such typical coefficients for commercial heat transfer services.

Read story → 0 comments

Specifying A Liquid-Liquid Heat Exchanger

Nov 07 2010 06:00 PM |

Chris Haslego

in Heat Transfer

As an engineer, specifying heat exchangers for procurement is an important step in the successful execution of any heat transfer or energy conservation project. Early recognition that there are many different heat transfer technologies available can he...

Article Images:

Read story →

1 comments

ChE Plus Has Moved

Dec 29 2010 10:10 PM |

Chris Haslego

in Articles

ChE Plus has moved to the Community section of our website. Here, we'll explain how to access your ChE Plus files in our new interface. If you do NOT have an account set up in our community section, read below about how to gain access.Already Have a...

Read story → 0 comments

Terms of Use and Legal Restrictions

Feb 17 2011 11:50 PM |

Chris Haslego

in Articles

ATTENTION: PLEASE READ THESE TERMS CAREFULLY BEFORE USING THIS WEB SITE. USING THIS WEB SITE INDICATES THAT YOU ACCEPT THESE TERMS. IF YOU DO NOT ACCEPT THESE TERMS ("TERMS"), DO NOT USE THIS WEB SITE. Use of Site. The Chemical Engineers' Resource Pa...

Article Images:

Read story →

0 comments

Submission Received

Aug 24 2011 10:50 PM |

Chris Haslego

in Articles

Thank you for your submission. We've received your information and will be in contact with you shortly.

Article Images:

Read story →

0 comments

Valve Sizing and Selection

Dec 05 2011 03:20 PM |

Chris Haslego

in Fluid Flow

Sizing flow valves is a science with many rules of thumb that few people agree on. In this article I'll try to define a more standard procedure for sizing a valve as well as helping to select the appropriate type of valve. **Please note that the corr...

Read story → 16 comments

Steam Tracing with MS Excel

May 24 2012 06:50 PM |

adelange

in Heat Transfer

Heat tracing is used to prevent heat loss from process fluids being transported in process fluid pipes, when there is risk of damage to piping, or interference with operation such as fouling or blockage, caused by the congealing, increase in viscosity, or separation of components, in the fluid below certain temperatures, or when there is risk of formation of corrosive substances or water due to condensation in corrosive services.

Article Images:

Read story →

3 comments

Ammonia: The Next Step

Nov 08 2010 01:20 PM |

Guest

in Process and Reactions

Steam reforming of hydrocarbons for ammonia production was introduced in 1930. Since then, the technology has experienced revolutionary changes in its energy consumption patterns. Ranging from an early level of 20 Gcal/tonne (79.4 MBtu/tonne) to about...

Article Images:

Read story →

0 comments

Design Considerations for Shell and Tube Heat E...

Nov 08 2010 01:30 PM |

Chris Haslego

in Heat Transfer

When preparing to design a heat exchanger, do you ever wonder where to start? You've done it before, but you hate that feeling of getting half way through the design and realizing that you forgot to consider one important element.The thought process i...

Article Images:

Read story →

3 comments

Energy Conservation in Distillation

Dec 13 2010 09:23 AM |

Chris Haslego

in Separation Technology

The preferred method of separation in the chemical industry, distillation, is a very energy intensive process. Fine tuning your distillation columns (and in some cases, making major changes) can save your company thousands of dollars a year or more. Co...

Article Images:

Read story →

0 comments

Product Viscosity Versus Shear

Feb 11 2013 06:50 PM |

Steve Hall

in Fluid Flow

Many products are known to be “shear thinning,” which is a term given to materials that exhibit a decrease in viscosity when force is exerted. The viscosity of pseudoplastic fluids decreases with shear, and recovers quickly when the shear is removed. Examples include paper pulp in water, latex paint, molasses, and pharmaceutical suspensions (such as certain cough syrups).

Article Images:

Read story →

6 comments

Hollow Fiber Membranes

Nov 08 2010 01:20 PM |

Chris Haslego

in Separation Technology

Membrane separation processes has become one of the emerging technology which undergo a rapid growth during the past few decades. It has drawn the world attention especially in the separation technology field, one of the chemical engineers' specialty w...

Article Images:

Read story →

1 comments

Air Leak Testing Prior to Commissioning

Nov 08 2010 01:30 PM |

Chris Haslego

in Maintenance and Repair

Our message board is a constant source of great advice and information for all of our users. Some times, an especially useful discussion takes place that deserves a little extra attention. The inquiry and reply shownin this articlecan benefit process e...

Article Images:

Read story →

0 comments

Relieve Valve Set Pressures

Nov 08 2010 01:20 PM |

pleckner

in Safety and Pressure Relief

As the title of this column implies, I intend to present various topics related to Process Engineering Design based on my knowledge and experiences. I will convey what approaches I think you should be taking. I will stress "the correct way" so don't ex...

Article Images:

Read story →

0 comments

Relief Valves: "What Can Go Wrong" Scen...

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

What can go wrong in a chemical facility? Plenty! A report in the August 2000 issue of CEP1 shows that operator error or poor maintenance was the leading of cause of accidents for unfired pressure vessels eight years running. The ProblemAccidents not o...

Article Images:

Read story →

0 comments

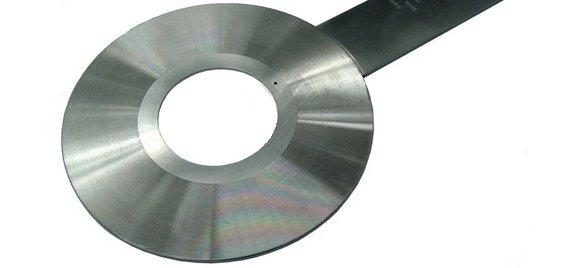

Rupture Disks for Process Engineers - Part 2

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. This part will discuss how to size the rupture disk. Subsequent parts will include how to set the burst pressure...

Article Images:

Read story →

0 comments

Rupture Disks for Process Engineers - Part 3

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. In this part, I will cover how to set the burst pressure. Subsequ...

Article Images:

Read story →

0 comments

Rupture Disks for Process Engineers - Part 4

Nov 08 2010 01:30 PM |

pleckner

in Safety and Pressure Relief

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device. Part 2 discussed how to size the rupture disk. Part 3 discussed how to set the burst pressure. In this part, I w...

Article Images:

Read story →

0 comments

FB

FB