|

|

Barometric Legs Line Sizing

#1

Posted 17 March 2023 - 02:46 PM

I would like to ask you if you could share with me your knowledge about barometric legs line sizing.

Thank you in advance!

#2

Posted 17 March 2023 - 06:15 PM

It should be self-venting.

Bobby

#3

Posted 18 March 2023 - 01:08 AM

HI,

Breizh

#4

Posted 18 March 2023 - 03:15 AM

Breizh thank you for providing me this info!

#5

Posted 18 March 2023 - 03:49 AM

Hi,

To understand the point made by Bobby, review the thread attached.

Self-venting Gravity Flow Pipe Calculation - Industrial Professionals - Cheresources.com Community

Breizh

#6

Posted 18 March 2023 - 07:48 AM

#7

Posted 18 March 2023 - 09:30 AM

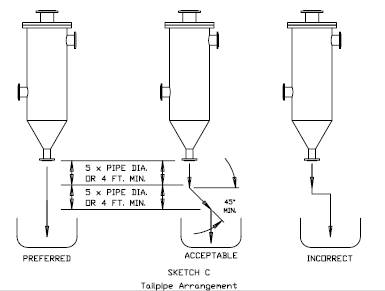

The Jeferson Costa article Breizh linked stresses the importance of the tailpipe arrangement in a seal leg. I do not understand why changes in piping direction would matter as long as there are no pockets which would collect vapor bubbles. Is the concern just for the additional pressure drop that could be overcome with more elevation? Or is there something special about minimum distance of pipe segments in this system that would make a short segment unacceptable? See the quote below:

"The tailpipe arrangement is very crucial and should not contain any horizontal runs. The ideal is straight down and the acceptable is 45-degree minimum off the horizontal, and the change in direction must be 5 pipe diameters or 4 feet minimum away from the water outlet flange and between all changes in direction."

#8

Posted 18 March 2023 - 09:06 PM

Hi Pilesar and others,

Consider this paper from Graham to support your questioning.

Breizh

Attached Files

#9

Posted 19 March 2023 - 02:48 AM

There are two problems with non-vertical piping, The main one is that bubbles behave differently in differently oriented piping. You can design a vertical pipe to be self-venting, but what will bubbles do in a horizontal pipe of the same diameter? I have had bad experiences with horizontal drain pipes and I would recommend that you avoid them completely. In one plant which I inherited I was able to replace a horizontal section with a 45 degree section and it did improve operation significantly but vertical would have been better.

The second, and less important, aspect is the longer the physical length of the pipe the larger capacity you need in the hot-well. This is generally an easier problem to overcome.

#10

Posted 19 March 2023 - 12:48 PM

What is the origin of this criterion?

#11

Posted 19 March 2023 - 01:16 PM

The Froude criteria is so that bubbles will rise and not be carried downward by the liquid stream.

Thank you katmar for your anecdote. I am troubleshooting someone else's unorthodox piping design and trying to understand how the existing piping affects results. It is so much easier to initially design to an understandable standard than it is to take an existing installation and try to justify whether a nonstandard design makes enough of a difference to require expensive changes.

The graham213 article Breizh attached is excellent with much depth to explore. While the Jeferson Costa article described a minimum length for a 45 degree pipe segment, I think that is a misinterpretation Costa made from the graham123 article which gives a minimum length for a vertical segment above a direction change (see quote below.) If a slanted segment is required, there is no advantage to making the slant piping longer to conform to a four foot minimum length.

#12

Posted 19 March 2023 - 01:54 PM

I did not get your last sentence: "When a change in direction is required,

there must always be a vertical straight

distance of five pipe diameters or four ft

minimum between each change."!!! Do you mean that the upper part of the vertical pipe should have larger diameter than the lower part?

#13

Posted 19 March 2023 - 02:09 PM

It is common to reference pipe length as a multiple of the pipe diameter. That way, the length dimension scales with the diameter of the pipe when using designing rules. Similar relative dimensions are used for vessel internals and nozzle locations where appropriate.

#14

Posted 19 March 2023 - 02:18 PM

#15

Posted 19 March 2023 - 02:52 PM

#16

Posted 19 March 2023 - 03:39 PM

Hi everyone! I have not read yet your documents deeply. But, I would love to share with you that a criterion to size vertical lines is Froude number<0.3.

What is the origin of this criterion?

The earliest reference I have seen for the Froude number value of 0.3 being the cut off point for self venting flow was an article by Larry Simpson in Chemical Engineering June 17, 1968 where he refers to experiments done by RD Webb. Unfortunately it seems that Webb did not publish his results but communicated them privately to Simpson in 1940. The criterion of 0.3 came from the point at which vibrations ceased.

I have also seen a literature review by Lauchlan published in 2005 that refers to articles from the 1940s and 50s on the subject, so it seems this is roughly the time of the experimental work on the topic. Actual values reported vary from 0.31 to 0.35.

#17

Posted 19 March 2023 - 04:10 PM

PS: I am gonna search for this (g)old article!????

#18

Posted 05 April 2024 - 03:32 AM

There are two problems with non-vertical piping, The main one is that bubbles behave differently in differently oriented piping. You can design a vertical pipe to be self-venting, but what will bubbles do in a horizontal pipe of the same diameter? I have had bad experiences with horizontal drain pipes and I would recommend that you avoid them completely. In one plant which I inherited I was able to replace a horizontal section with a 45 degree section and it did improve operation significantly but vertical would have been better.

The second, and less important, aspect is the longer the physical length of the pipe the larger capacity you need in the hot-well. This is generally an easier problem to overcome.

Dear Sir,

I need more understanding with respective the barometric leg. As I understood, it should be 11 meter in lenght vertically to be safer side considering full vacuum at condensor. In case vertical not possible then we can use 45 degree inclined.

My question is if I place condenser at 13-14 meter above leg drain seal pot (Hotwell), about 2-3 meter more than requirment of 11 meter and drain leg is horizontal from condenser outlet for about 4-5 meter and then inclined at 90 degree straight to Hotwell. Veritical distance is still more than 11 meter from 90 Degree elbow to Hotwell. Will this arrangement work or there will be still bubble issue or back pressur issue.

Please revert.

#19

Posted 05 April 2024 - 05:09 AM

If the horizontal section immediately below the condenser is large enough you can probably make it work, but I have not seen it done.

In the article "Designing piping for gravity flow" by PD Hills there is a section discussing side-outlet piping which may be helpful to you. There was an Excel version of this article that was posted to Cheresources by Art Montemayor but I can't find the link to it any more. But if you search using Google for "PD Hills gravity piping" you will find a copy on the Engineering.com page.

#20

Posted 05 April 2024 - 06:15 AM

Hi,

To add to Katmar's reply, Attached the document issued by Art.

Breizh

Attached Files

#21

Posted 02 September 2024 - 02:57 PM

HI,

To support: HTTPs://jefersoncosta.com/what-barometric-leg-is-and-how-to-design-it-as-a-chemical-process-engineer/#:~:text=The%20barometric%20legs%20should%20be,the%20drain%20legs%20for%20blockage.

Breizh

Similar Topics

Steam Drum SizingStarted by Guest_nastaran_* , 01 Dec 2025 |

|

|

||

Sizing Of Condensate Return VesselsStarted by Guest_panoska_* , 23 Oct 2025 |

|

|

||

Horizontal Decanter Sizing CalculationStarted by Guest_peejoee_* , 07 Oct 2025 |

|

|

||

Sizing And And Process Control Of Filter PressStarted by Guest_Amalina Jamil_* , 11 Mar 2019 |

|

|

||

Nozzle Sizing CalculationStarted by Guest_BabRafiq1_* , 26 Aug 2022 |

|

|

FB

FB